Currently, the commercial and research state-of-the-art systems deal with the subcritical ORC variant. The main difference of the aforementioned “conventional” subcritical with the supercritical ORC is the operation of the latter at supercritical conditions. The anticipated performance improvements, compared to a subcritical ORC, will be the outcome of three discrete fields of intervention:

- Operation at supercritical conditions → System efficiency increase by around 10%

- Efficient heat input to the organic fluid keeping as low as possible the heat exchanger surface → System efficiency increase by 10%

- Development of an optimized small-scale scroll expander → System efficiency increase by around 10-15%

The sum of the above estimated improvements can bring an overall efficiency increase in the order of 30-35%, in comparison to a standard subcritical ORC. However, the consortium guarantees an actual efficiency improvement of 25% of the prototype. This means that a subcritical ORC of an actual overall system efficiency of 6% (top temperature of 100 oC) will reach the level of 7.5%.

|

|

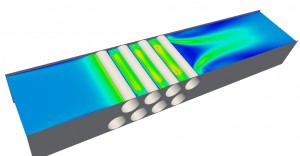

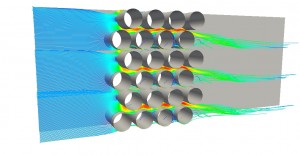

| Shell and tube CFD calculations | |

|

|

|

|

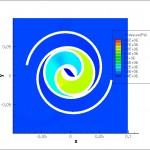

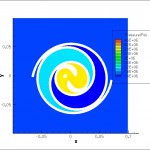

| Scroll expander CFD calculations |  |

|

|

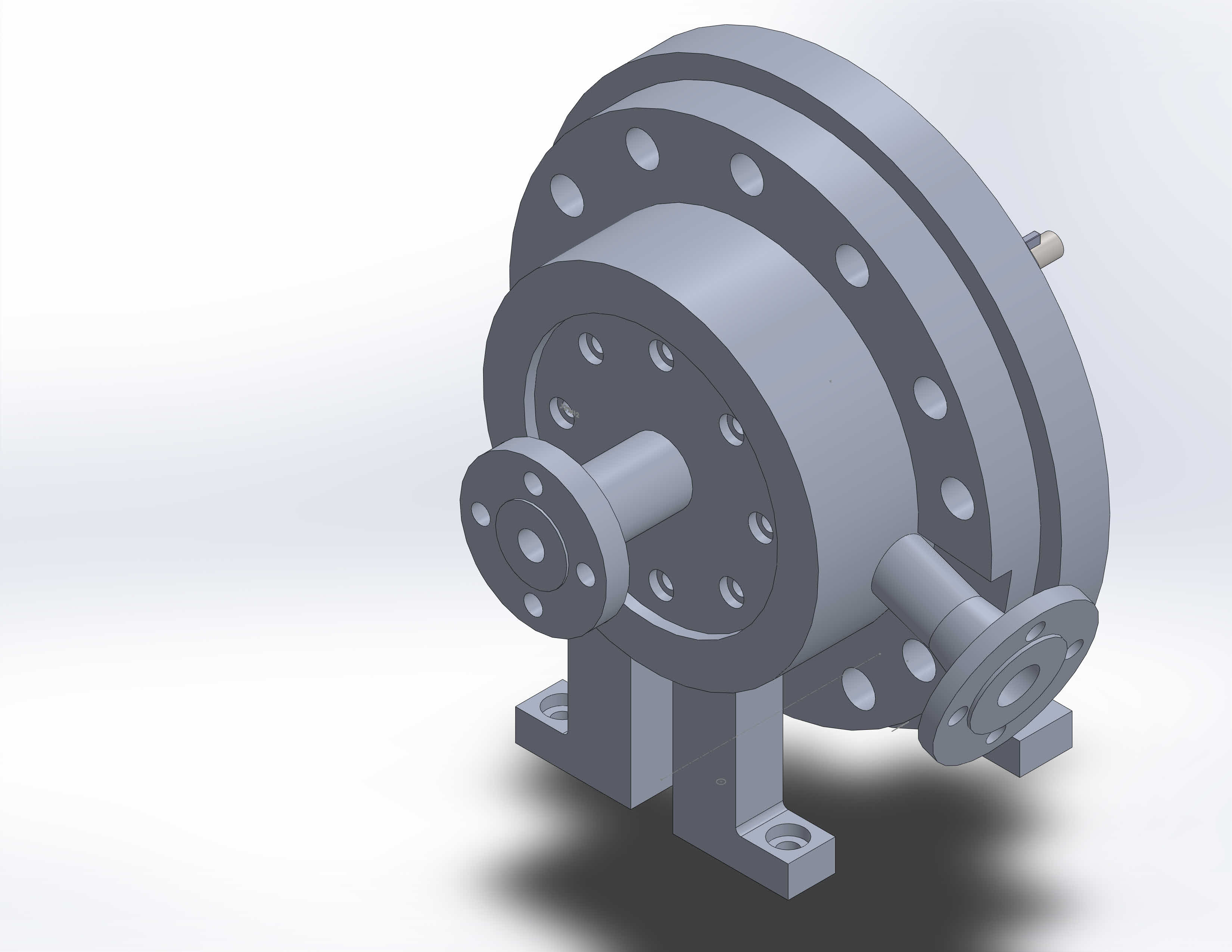

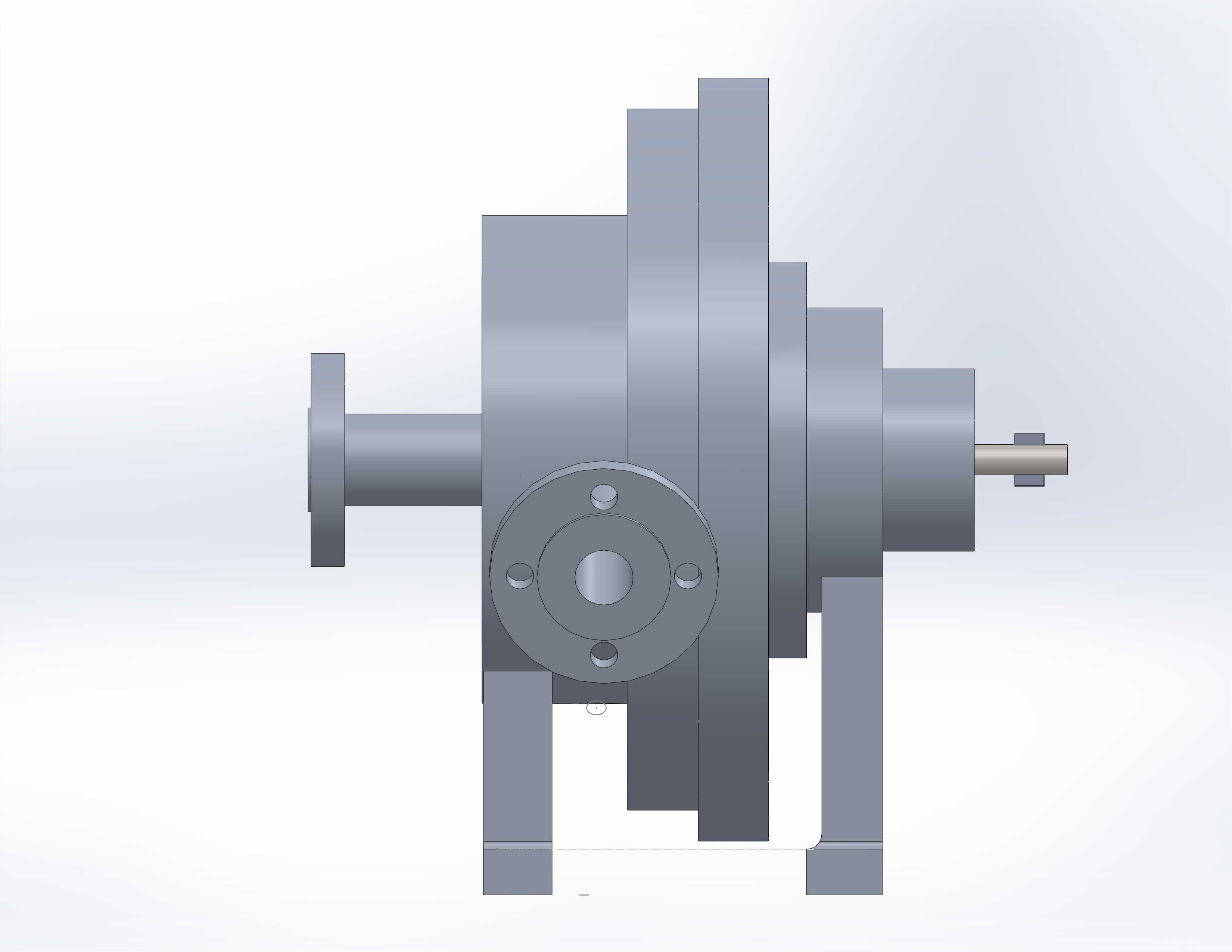

| Scroll expander design | |||