Development of a small-scale low-temperature Supercritical Organic Rankine Cycle engine with optimised scroll expander and evaporator

The project titled “Development of a small-scale low-temperature Supercritical Organic Rankine Cycle engine with optimised scroll expander and evaporator” [SUPERCRITICAL-ORC] in the framework of the program “SYNERGASIA 2011”, aims to develop and bring into the market a small scale (5-10 kW) low temperature (80-100 oC) SuperCritical Organic Rankine Cycle (SCORC) engine, so that the huge potential of low temperature thermal sources (such as waste heat, geothermal energy, solar energy, etc.) to be efficiently and cost effectively exploited for power generation. The main technological innovation concerns the operation of the engine at supercritical conditions, requiring a detailed investigation of the main processes, in order to maximize the system performance.

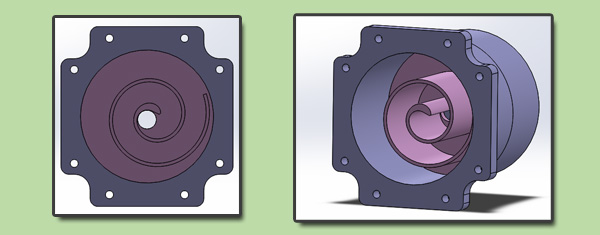

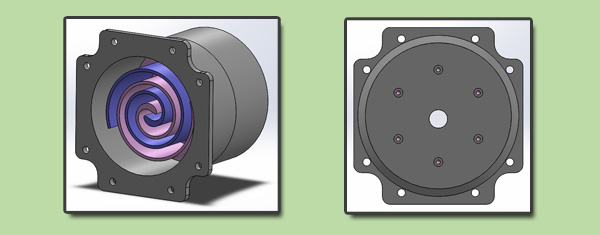

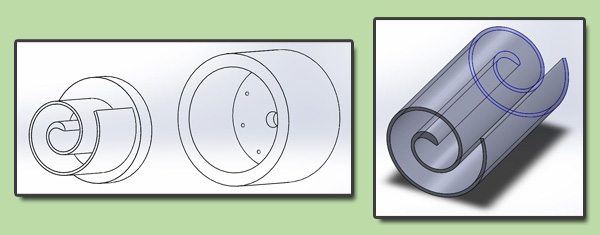

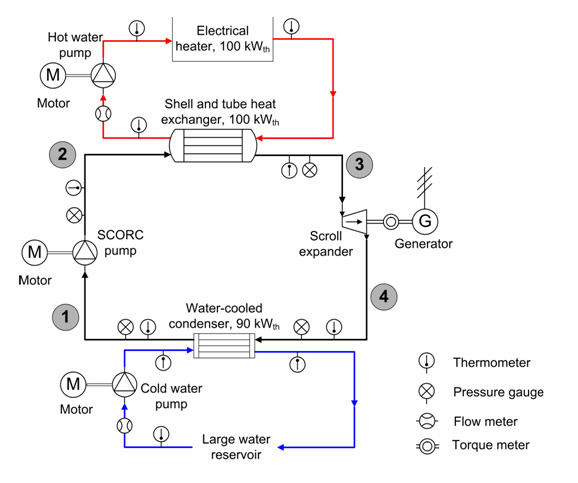

The main process of a SCORC engine is depicted in the following figure, while during the project focus will be given to the evaporator and the scroll expander.

The project duration is 27 months (start: April 2013) and is partly funded by the General Secretary for Research and Technology (GSRT) (www.gsrt.gr) under contract number 11SYN_7_278.

NEWS

-

Progress

– The WP1 has been successfully completed on time. The first design aspects have been concluded, which can be then used as boundary conditions for the CFD simulations.

– The WP2 has been successfully completed. The supercritical heat exchanger and scroll expander have been optimized and their design concluded.

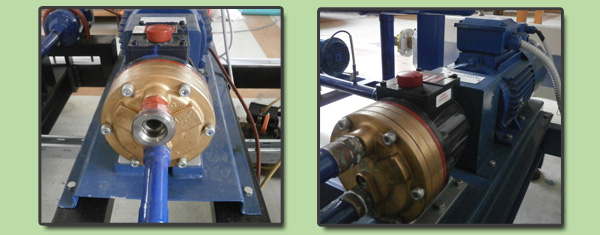

– The WP3 has been successfully completed. The two key components of the SCORC engine (open-drive scroll expander and evaporator) have been manufactured according to the designs of WP2.

– The WP4 has been successfully completed. The whole SCORC engine has been manufactured and it is ready for the lab tests.

– The WP5 has been successfully completed. The economic analysis and feasibility study for the benefit of the participating SMEs have been conducted. Moreover, the SCORC engine has been tested at the NTUA lab for hot water temperature of 65-100 oC.

– The WP6 includes other activities, such as project dissemination, IP strategy, and planning of the production processes.

EVENTS

-

KICK-OFF MEETING

The kick-off meeting of the project partners took place in the Agricultural University of Athens (AUA) on the 27th January 2014. Representatives from all partners participated in this meeting.