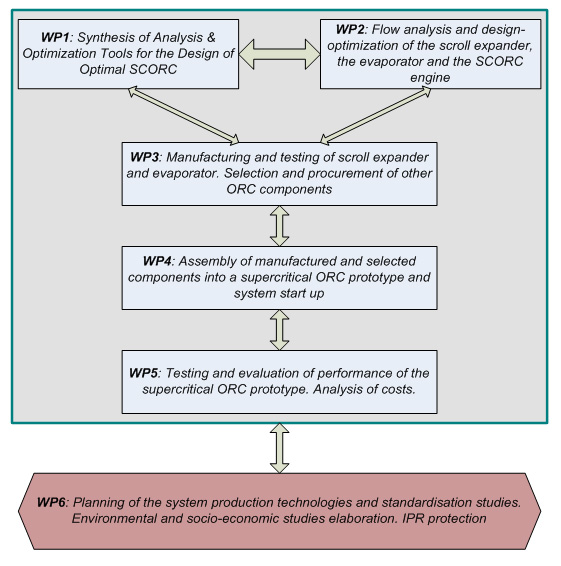

The RTD work starts in WP1 where the critical SCORC parameters will be identified along with methods and tools for the “coarse level” analysis and optimization. This will be carried out so as to come up with a first quasi-optimal SCORC system. In WP2 the two key components (scroll expander and evaporator) of the low-temperature SCORC engine will be investigated with detail. CFD code and optimization software will be applied for the optimization of their design. WP3 involves the manufacturing and testing of an adequate number of designed key components, until the optimal ones are identified and tested, while the selection of other supplementary components will be made.

The next step of the RTD work (WP4) will be to put together all SCORC components to assemble a prototype engine, which will be installed at NTUA and extensively tested (WP5), with feedback to the design-optimization process, for further improvement based on measurements.

The last WP (WP6) foresees the elaboration of environmental and socio-economic studies, IPR issues, standardization, feasibility studies and other activities, which will help the participating SMEs to benefit from the project results.